BUSINESS SCHOOL

Mock Exam paper

BEA2010 MANAGERIAL ACCOUNTING

1. How is the term reciprocal services defined?

A. The term reciprocal services refers to the situation in which two or more service departments provide services to each other

B. The term reciprocal services refers to the allocation of costs to production departments only

C. None of the above

2. The Cartridges division of Petronk Inc. produces cartridges that can be widely used by manufacturers of various products. Sales and cost data on the cartridges are as follows:

Selling price per unit on the market £120

Variable costs per unit £90

Fixed costs (based on capacity) £12

Annual production capacity in units 80,000

The Printers division of Petronk Inc. can use the cartridges in one of its products. The Printers division will need 10,000 cartridges per year. It has received a quote of £105 per cartridge from another manufacturer. Managers of Petronk Inc. are evaluated based on divisional profits.

Assume that the Cartridges division is selling all the cartridges it produces to external customers. From the standpoint of the Cartridges division, what is the lowest acceptable transfer price for cartridges sold to the Printers division?

A. £105

B. £120

C. £90

D. £12

3. The Cartridges division of Petronk Inc. produces cartridges that can be widely used by manufacturers of various products. Sales and cost data on the cartridges are as follows:

Selling price per unit on the market £120

Variable costs per unit £90

Fixed costs (based on capacity) £12

Annual production capacity in units 80,000

The Printers division of Petronk Inc. can use the cartridges in one of its products. The Printers division will need 10,000 cartridges per year. It has received a quote of £105 per cartridge from another manufacturer. Managers of Petronk Inc. are evaluated based on divisional profits.

Assume that the Cartridges division is selling all the cartridges it produces to external customers. From the standpoint of the Printers division, what is the highest acceptable transfer price for cartridges purchased from the Cartridges division?

A. £12

B. £105

C. £102

D. £90

4. The Cartridges division of Petronk Inc. produces cartridges that can be widely used by manufacturers of various products. Sales and cost data on the cartridges are as follows:

Selling price per unit on the market £120

Variable costs per unit £90

Fixed costs (based on capacity) £12

Annual production capacity in units 80,000

The Printers division of Petronk Inc. can use the cartridges in one of its products. The Printers division will need 10,000 cartridges per year. It has received a quote of £105 per cartridge from another manufacturer. Managers of Petronk Inc. are evaluated based on divisional profits.

Assume that the Cartridges division is selling all the cartridges it produces to external customers. From the standpoint of the entire company, should the transfer take place?

A. YES

B. NO

C. IT IS NOT CLEAR BASED ON THE INFORMATION AVAILABLE

5. The Cartridges division of Petronk Inc. produces cartridges that can be widely used by manufacturers of various products. Sales and cost data on the cartridges are as follows:

Selling price per unit on the market £120

Variable costs per unit £90

Fixed costs (based on capacity) £12

Annual production capacity in units 80,000

The Printers division of Petronk Inc. can use the cartridges in one of its products. The Printers division will need 10,000 cartridges per year. It has received a quote of £105 per cartridge from another manufacturer. Managers of Petronk Inc. are evaluated based on divisional profits.

Assume that the Cartridges division is selling only 70,000 cartridges per year to outside customers. From the standpoint of the Cartridges division, what is the lowest acceptable transfer price for cartridges sold to the Printers division?

A. £12

B. £120

C. £102

D. £90

6. The Cartridges division of Petronk Inc. produces cartridges that can be widely used by manufacturers of various products. Sales and cost data on the cartridges are as follows:

Selling price per unit on the market £120

Variable costs per unit £90

Fixed costs (based on capacity) £12

Annual production capacity in units 80,000

The Printers division of Petronk Inc. can use the cartridges in one of its products. The Printers division will need 10,000 cartridges per year. It has received a quote of £105 per cartridge from another manufacturer. Managers of Petronk Inc. are evaluated based on divisional profits.

Assume that the Cartridges division is selling only 70,000 cartridges per year to outside customers. From the standpoint of the Printers division, what is the highest acceptable transfer price for cartridges purchased from the Cartridges division?

A. £120

B. £12

C. £105

D. £0

7. The Cartridges division of Petronk Inc. produces cartridges that can be widely used by manufacturers of various products. Sales and cost data on the cartridges are as follows:

Selling price per unit on the market £120

Variable costs per unit £90

Fixed costs (based on capacity) £12

Annual production capacity in units 80,000

The Printers division of Petronk Inc. can use the cartridges in one of its products. The Printers division will need 10,000 cartridges per year. It has received a quote of £105 per cartridge from another manufacturer. Managers of Petronk Inc. are evaluated based on divisional profits.

Assume that the Cartridges division is selling only 70,000 cartridges per year to outside customers. From the standpoint of the entire company, should the transfer take place?

A. YES

B. NO

C. IT IS NOT CLEAR BASED ON THE INFORMATION AVAILABLE

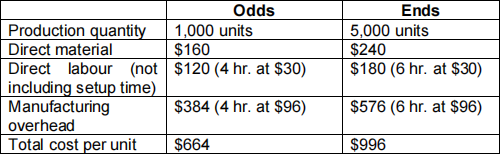

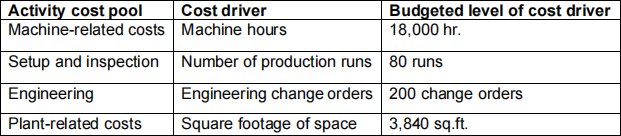

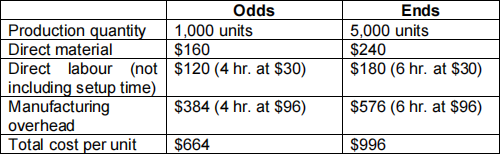

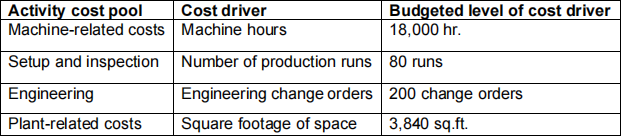

8. Knickknack Inc., manufactures two products: odds and ends. Production and product costing data are as follows:

The manufacturing overhead budget is provided below:

Machine-related costs $1,800,000

Setup and inspection $ 720,000

Engineering $ 360,000

Plant-related costs $ 384,000

Total $3,264,000

The following cost drivers have been identified for the four activity cost pools.

The following additional information is provided:

- Each odd requires 8 machine hours, whereas each end requires 2 machine hours.

- Odds are manufactured in production runs of 25 units each. Ends are manufactured in 125 unit batches.

- Three quarters (i.e. 75%) of the engineering activity, as measured in terms of change orders, is related to odds.

- The plant has 3,840 square feet of space, 80% of which is used in the production of odds.

What is the pool rate for machine-related costs?

A. $100

B. $1,800

C. $1,000

D. $18,000

9. Knickknack Inc., manufactures two products: odds and ends. Production and product costing data are as follows:

The manufacturing overhead budget is provided below:

Machine-related costs $1,800,000

Setup and inspection $ 720,000

Engineering $ 360,000

Plant-related costs $ 384,000

Total $3,264,000

The following cost drivers have been identified for the four activity cost pools.

The following additional information is provided:

- Each odd requires 8 machine hours, whereas each end requires 2 machine hours.

- Odds are manufactured in production runs of 25 units each. Ends are manufactured in 125 unit batches.

- Three quarters (i.e. 75%) of the engineering activity, as measured in terms of change orders, is related to odds.

- The plant has 3,840 square feet of space, 80% of which is used in the production of odds.

What is the pool rate for setup and inspection costs?

A. $720,000

B. $7,200

C. $80

D. $9,000

10. Knickknack Inc., manufactures two products: odds and ends. Production and product costing data are as follows:

The manufacturing overhead budget is provided below:

Machine-related costs $1,800,000

Setup and inspection $ 720,000

Engineering $ 360,000

Plant-related costs $ 384,000

Total $3,264,000

The following cost drivers have been identified for the four activity cost pools.

The following additional information is provided:

- Each odd requires 8 machine hours, whereas each end requires 2 machine hours.

- Odds are manufactured in production runs of 25 units each. Ends are manufactured in 125 unit batches.

- Three quarters (i.e. 75%) of the engineering activity, as measured in terms of change orders, is related to odds.

- The plant has 3,840 square feet of space, 80% of which is used in the production of odds.

What is the pool rate for engineering costs?

A. $360,000

B. $1,800

C. $360

D. $200

11. Knickknack Inc., manufactures two products: odds and ends. Production and product costing data are as follows:

The manufacturing overhead budget is provided below:

Machine-related costs $1,800,000

Setup and inspection $ 720,000

Engineering $ 360,000

Plant-related costs $ 384,000

Total $3,264,000

The following cost drivers have been identified for the four activity cost pools.

The following additional information is provided:

- Each odd requires 8 machine hours, whereas each end requires 2 machine hours.

- Odds are manufactured in production runs of 25 units each. Ends are manufactured in 125 unit batches.

- Three quarters (i.e. 75%) of the engineering activity, as measured in terms of change orders, is related to odds.

- The plant has 3,840 square feet of space, 80% of which is used in the production of odds.

What is the pool rate for plant-related costs?

A. $3,840

B. $384,000

C. $100

D. $0

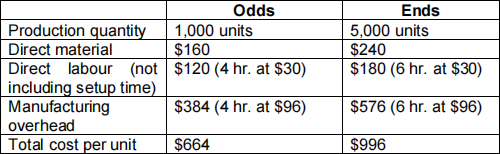

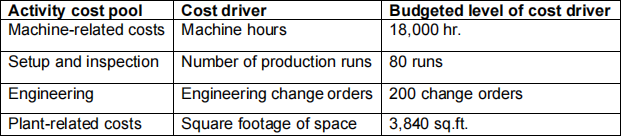

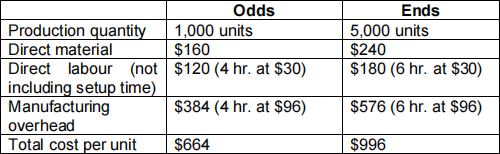

12. Knickknack Inc., manufactures two products: odds and ends. Production and product costing data are as follows:

|

|

Odds |

Ends |

|

Production quantity |

1,000 units |

5,000 units |

|

Direct material |

$160 |

$240 |

|

Direct labour (not including setup time) |

$120 (4 hr. at $30) |

$180 (6 hr. at $30) |

|

Manufacturing overhead |

$384 (4 hr. at $96) |

$576 (6 hr. at $96) |

|

Total cost per unit |

$664 |

$996 |

The manufacturing overhead budget is provided below:

Machine-related costs $1,800,000

Setup and inspection $ 720,000

Engineering $ 360,000

Plant-related costs $ 384,000

Total $3,264,000

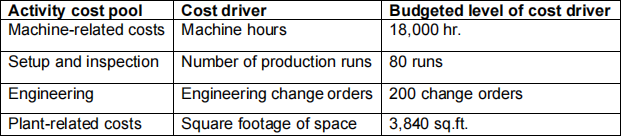

The following cost drivers have been identified for the four activity cost pools.

|

Activity cost pool |

Cost driver |

Budgeted level of cost driver |

|

Machine-related costs |

Machine hours |

18,000 hr. |

|

Setup and inspection |

Number of production runs |

80 runs |

|

Engineering |

Engineering change orders |

200 change orders |

|

Plant-related costs |

Square footage of space |

3,840 sq.ft. |

The following additional information is provided:

- Each odd requires 8 machine hours, whereas each end requires 2 machine hours.

- Odds are manufactured in production runs of 25 units each. Ends are manufactured in 125 unit batches.

- Three quarters (i.e. 75%) of the engineering activity, as measured in terms of change orders, is related to odds.

- The plant has 3,840 square feet of space, 80% of which is used in the production of odds.

What is the unit machine-related costs for odds?

A. $800

B. $8,000

C. $100

D. $200